By Kate Yuan

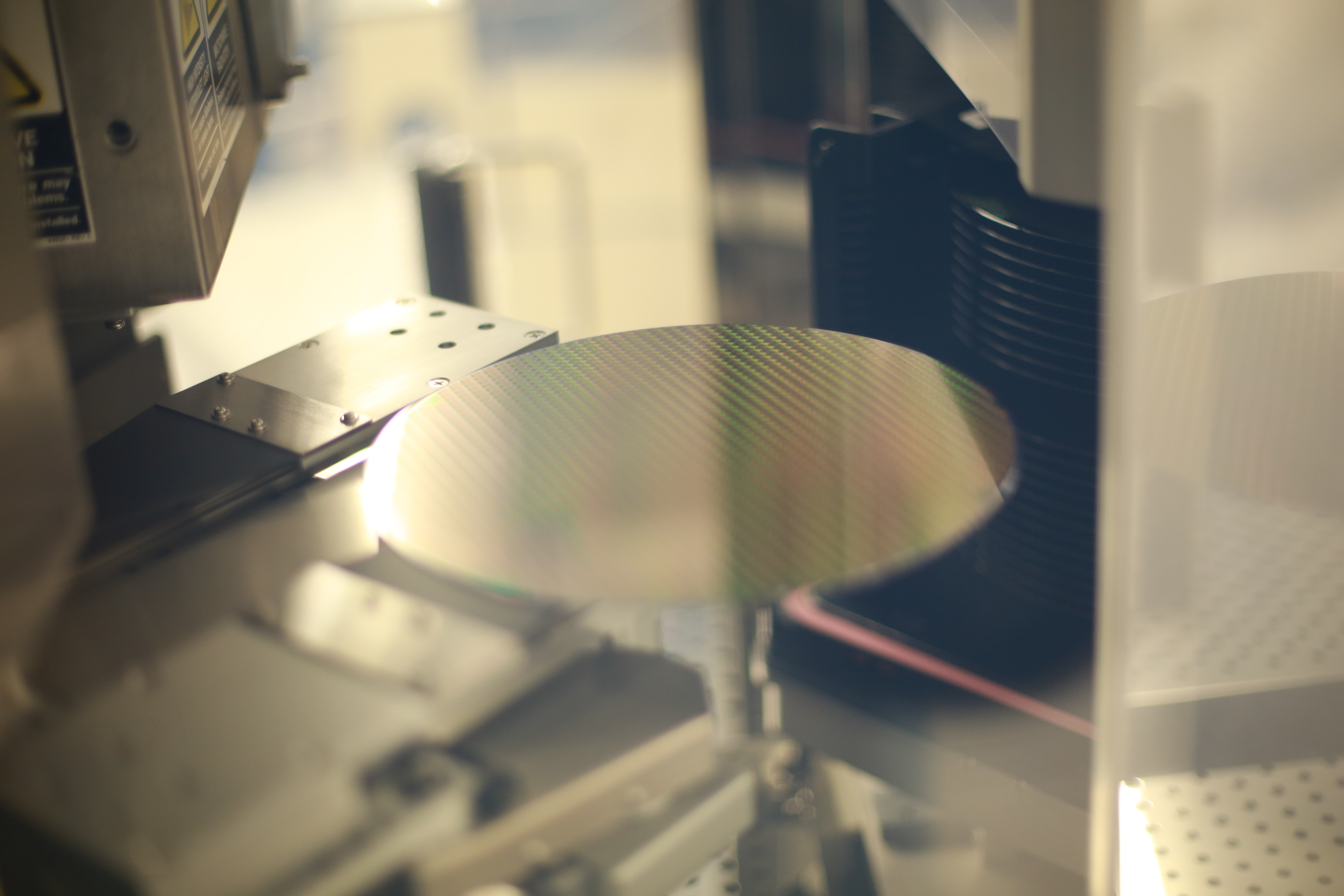

Chinese packaging material providers are under extreme pressure caused by pandemic control and order shortages, JW Insights has learned.

The boom of the global semiconductor industry during 2020-2021 drove the surging demands in the packaging and testing markets and resulted in the tight supply of upstream packaging materials, including lead frames and molding compounds. Since this year the weakened industry demands and tight pandemic control have cuaused reduced orders and low utilized capacity. Oversupply has occurred in the upstream packaging material sector.

Lead frame was one of the scarce upstream materials in the packaging and testing market in 2021. JW Insights reported in early April this year that the current lead frame basically reached supply and demand balance.

However, the continued price drop of its main raw material, LME copper, has pushed the lead frame makers to reduce prices too, dragging down their revenues.

In addition, destocking in the consumer electronics market has also caused the oversupply of upstream materials.

Kangqiang Electronics (康强电子) is a leading Chinese manufacturer of packaging materials including lead frames and bonding wires. Its revenue decreased by 11.45% year on year in the first half of the year. The lead frame business dropped by 15.59% over the previous year.

Apart from lead frames, Chinese bonding wires and epoxy molding compound makers did not perform well either.

Bonding wires provider MK Electron (铭凯益) suffered a net loss of RMB2.2 million ($306,889) in the first half of 2022, with income down by 23.72% year on year.

MK Electron said it suspended operations in April to cooperate with the local government's pandemic control policies. In May, the pandemic outbreak in Shanghai and other places again blocked the supply chain, causing the storage of raw materials.

The epoxy molding compound companies are also facing the continued price hikes of upstream raw materials.

However, due to the fierce competition in the low-end and middle-end market, downstream customers have turned to domestic epoxy molding compounds to further reduce costs.

Most epoxy molding compound makers find it not only difficult to pass on the rising cost to downstream players and had to drop prices as well.

Tecore Synchem (德高化成), a listed epoxy molding compound provider, reported a net loss of RMB1.2 million ($169,046), also turning profits into losses.

RELATED

-

Chinese top-tier chipmaker HuaHong Semiconductor's net profit plummets 86 percent in the third quarter

11-17 19:11 -

Chinese MEMS provider Fatri UTC will set up its sensor chip production plant in Shanghai

11-16 18:30 -

China's packaging and testing services provider Forehope Electronic will build a new plant with RMB2.157 billion investment

11-15 17:17

READ MOST

No Data Yet~