Chips have entered the Age of Convergence. From unmanned driving to virtual reality, from artificial intelligence to cloud computing, from 5G to IoT, there are many forces driving the continuous advancement of semiconductor testing technology. As more and more functions are carried on a chip, and technology grows more and more complex, the number and types of test steps must be multiplied, which, in turn, leads to increased test costs. Semiconductor test equipment requires ultra-long "standby," which is an asset-heavy investment in semiconductor manufacturing plants, with a life cycle of at least 5 to 10 years. In an intelligent world where chip technology and processes are rapidly upgraded and iterated, such equipment must be able to meet increasingly complex testing needs at any time.

Testing always needs to be ahead of the chip. So, given the long "standby," what techniques need to continuously update test equipment? In the battle to balance yield improvement and cost control, developing advanced capabilities in test equipment has become imperative. This means that test and measurement solutions must expand to address the entire semiconductor industry value chain. While still addressing the traditional “center” of testing (IC production processes, wafer test and final test), test technology must shift both left (to enable greater integration with IC design) and right toward more system-level testing (SLT) at the product level, as well as go upward to access the cloud, AI and big data.

The value of a large amount of semiconductor test data needs to be tapped and utilized, because it can not only improve test efficiency and ensure product yield, but it is also vital to optimizing test plans and controlling costs through data analysis. This is also a foundational imperative for Advantest and PDF Solutions, a provider of comprehensive data solutions for the semiconductor ecosystem.

The cooperation between the two companies has already produced some preliminary results and products. By combining PDF Solutions’ Exensio platform and its Data Exchange Network (DEX) with Advantest's advanced test equipment (ATE), customers can connect and analyze data anywhere in the semiconductor supply chain, helping them improve product yield and reduce test costs.

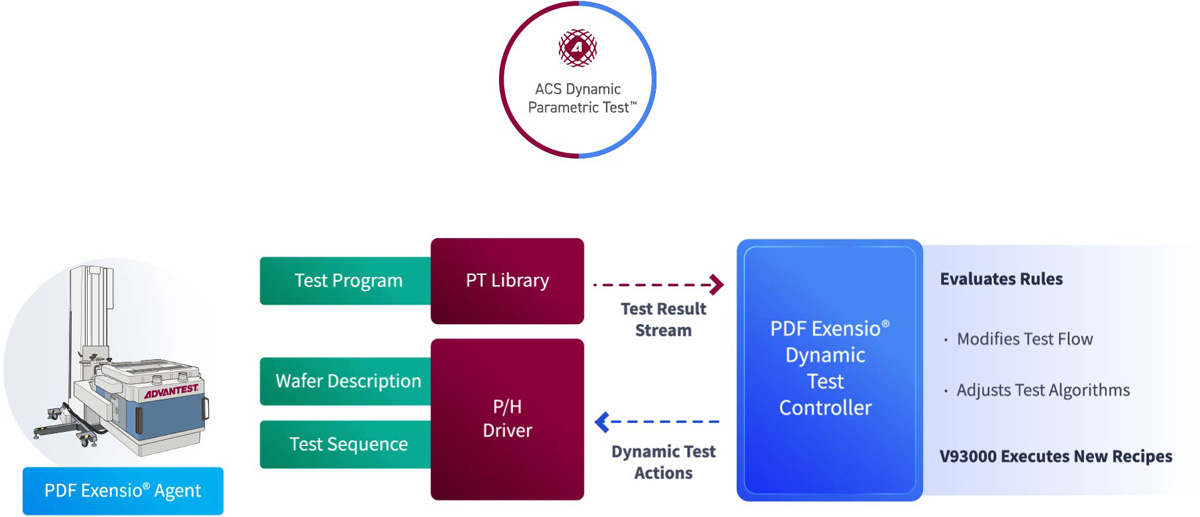

The two companies recently launched their first jointly developed product: Advantest Cloud Solutions (ACS) Dynamic Parametric Test (DPT). The solution integrates PDF Solutions' Exensio data analysis products with Advantest's V93000 parametric test system, enabling real-time optimization of parametric tests on the V93000 test platform and reducing manual interaction. (Note: Advantest Cloud Solutions is a cloud-based ecosystem of products and services, co-developed by Advantest and PDF Solutions, built on a platform focused on data and analytics, powered by PDF Exensio.)

Recently, JIWEI conducted an in-depth interview with several executives of Advantest and PDF Solutions. Included were Keith Schaub, vice president of strategy and technology at Advantest, and Sonny Banwari, vice president of business development for Advantest Cloud Solutions, along with Yu Guanyuan (Michael Yu), vice president of sales and operations from PDF Solutions, and David Park, vice president of marketing from PDF Solutions. Those four executives conducted in-depth analysis and discussion of their cooperation, technology and market development trends, and the pain points of big data analysis in semiconductor industry.

JIWEI: Can you describe the key benefits for the Advantest-PDF collaboration, and why we think they are important for the semiconductor industry?

Keith: Advantest has a long history in semiconductor testing, and we are the market leader in high volume manufacturing of semiconductor test products, with a range that spans from post-silicon validation, all the way to system level test. Now, there is a lot of big data coming out of the test eco-system, and the industry has realized the future is using tools like AI and machine learning to mine data value, to improve the operational efficiency of the entire ecosystem, and of the entire supply chain. PDF Solutions is well established and strong in data analytics, and an ideal partner for bringing this advanced technology to the fore.

Michael: Advantest is the world’s leading supplier of semiconductor test equipment. Over the decades it has amassed an enormous amount of knowledge and data related to semiconductor testing. PDF has always focused on data analysis of the entire semiconductor industry chain. With the industry advancing rapidly, the demand for semiconductor data analysis has begun to increase, so the cooperation between the two companies was a natural development. The key point of this cooperation is to interconnect test-related data with the entire industry chain. For example, some data before testing, such as manufacturing-related data, can help to decide which devices to test and how to improve testing efficiency and quality. At the same time, data from these test cells can be brought forward to the subsequent steps of the supply chain and can also be fed back to obtain a more reliable and efficient test plan.

Sonny: In semiconductor manufacturing, it usually takes 2.5 months to make a device. In fact, in the process you have many chances to find out whether a device is good or bad, and some defects begin to appear quite early in the process. When I started in the industry 33 years ago as a very young engineer at Intel, I really wanted to find a way to predict how a part can go bad at the very end and how we can catch it as early as possible. In the past, those capabilities were done manually. Now with PDF Solutions, leveraging big data, machine learning and some other methods, we can make smarter and faster predictions regarding device quality. We have jointly developed some excellent products, such as DPT.

David: I would like to add that, in fact, we are breaking down the data barriers that run through the entire semiconductor industry chain. This is of great significance for improving the overall yield and efficiency of the semiconductor industry. If you're able to easily move data across these data silos, whether it is product data, equipment data or test data, you can use these data to make the predictive types of decisions that Sonny was referring to. This is not only beneficial to certain companies, but can be useful to all companies in the semiconductor eco-system. For example, certain product that have high requirements on reliability and quality typically require burn-in, but burn-in is a very expensive step in the overall manufacturing and testing process. However, if you can aggregate end-to-end product data, from manufacturing to final test, AI/ML-based data analytics can be used to determine if it is necessary to do burn-in on every device without negatively impacting quality. It creates greater value for not only the supply chain, but also for the end customer. Because they will end up with robust products that have higher quality.

JIWEI: What additional values do we believe this collaboration bring to the market? Can you give an example to elaborate the benefit to your customers?

Keith: Advantest brings thousands of testers and multiple test insertions across the entire product test life cycle and generates all the data including test and equipment data. PDF Solutions brings the semiconductor data analytics tools with the experience and know-how. So, the synergy is ideal for customers as they can get the entire solution as well as plug-in any existing complementary tools, protecting the customer’s long-term investments. DPAT is an excellent example of the collaboration where PDF Solutions’ dynamic parametric test analytics capability has been seamlessly integrated into ACS Edge . Customers get a set of ready to go APIs that gets them up and running in production much faster.

JIWEI: Undoubtedly, the semiconductor industry is a data-intensive industry, but it is relatively backward in data analysis. What are the major obstacles? How will Advantest and PDF Solutions' new data analytics-based products impact the industry?

Keith: A lot of data and forecasts show that the global semiconductor industry is in a period of rapid growth, and the huge market size brings huge growth opportunity for companies throughout the entire industry supply chain. At the same time, end-user applications are increasingly diverse and complex, with higher requirements for the quality and reliability of electronic components such as IC chips. Taking automobiles as an example, its requirements for quality and reliability are much stricter than consumer electronic products, so it is necessary to make the test scheme coverage more comprehensive, which correspondingly increases the test cost. How do we control the cost of testing under the premise of ensuring higher quality? This requires introducing new methodologies. This is also what mining the value of semiconductor data can bring.

Advantest Cloud Solutions powered by PDF Exensio is equivalent to providing the industry with an infrastructure platform for data analysis of the entire semiconductor supply chain. PDF Exensio can help collect data from semiconductor chip fabrication, test, and system-level test. With advanced algorithms, integrated workflows, and solutions delivered by ACS, more valuable information can be gained from the data generated by supply chain equipment and testing, resulting in shorter production times and higher overall equipment efficiency.

Sonny: Take the global chip shortage in the past years as an example. This is a crisis for all industries, especially the automotive industry. In fact, this crisis has further forced carmakers to optimize products and technologies to deal with the chip shortage. The cooperation between Advantest and PDF Solutions is doing a similar thing - improving product yield through data analysis and providing customers with better products. This is not just reducing costs and improving profitability for a company, but giving an opportunity for the entire semiconductor ecosystem to upgrade.

Michael: Indeed, to ensure the quality and reliability of chips, especially automotive chips, you need extensive testing, and that takes tremendous time and effort. But if we can adopt a traceable system and integrate the data of the entire production process, we can use AI and machine learning to tell us what to test, and what's the most efficient way to perform the test. Instead of just one size fits all, with the data analysis obtained through AI and machine learning, we can carry out personalized test plans for different quality requirements and find the best test results in the shortest time. In addition, the trend of migrating to the cloud has been obvious to all. With the explosive growth of data volume at any time, the use of cloud technology to achieve more efficient computing and analysis is an industry trend, which is also an important aspect of our cooperation.

David: About five years ago, people were hesitant about going to cloud, mainly due to concerns about data security and privacy, especially in the semiconductor industry. This is the biggest obstacle for data analysis in the semiconductor industry. How to get enterprises across the supply chain willing to share data is a key step, and this is one aspect of what we are trying to do, to create a safe data sharing ecosystem. For example, both Advantest and PDF are involved in an initiative out of the GSA (Global Semiconductor Alliance) called TIES (Trusted IOT Ecosystem for Security), with the goal to bring together all the different players from design to manufacturing, packaging, and testing in the semiconductor supply chain to jointly form a secure trusted data sharing ecosystem.

In addition, it is worth mentioning that in the past two years, under the ongoing influence of the coronavirus, working remotely has greatly promoted investments in cloud infrastructure. And the semiconductor industry is a bit more open to moving data to the cloud. Being in the cloud will bring a more efficient and convenient data ecosystem to the entire semiconductor supply chain, for both scalability and computing performance.

JIWEI: Specifically, how will this collaboration impact the China market? Do you have customized products for China market/companies?

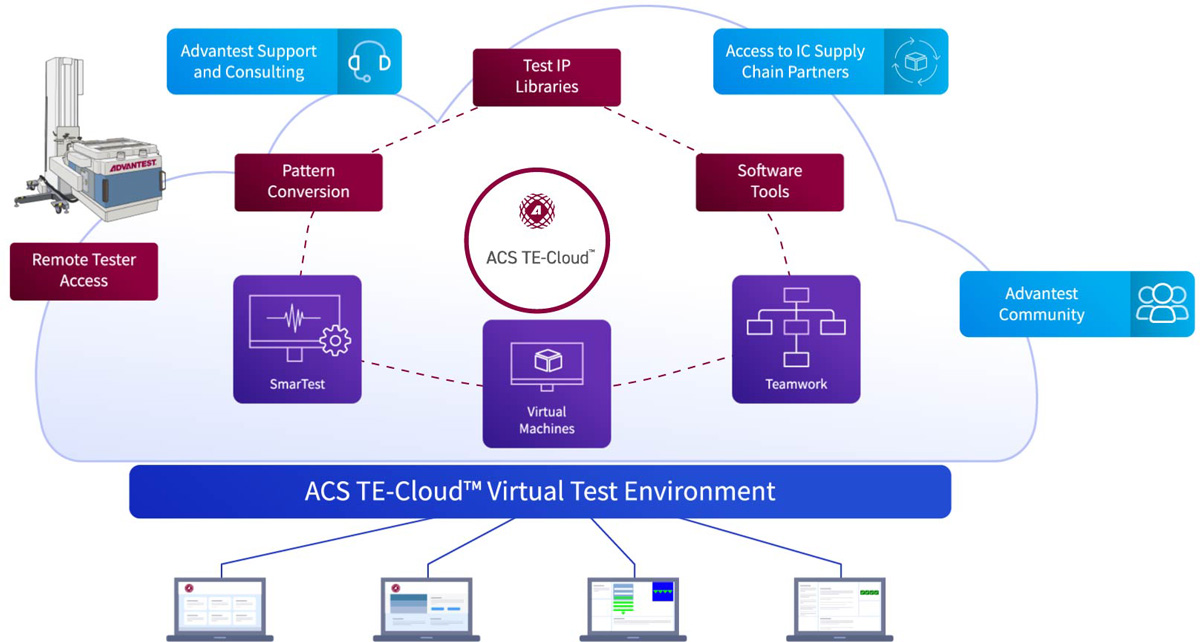

Keith: Let me start with the actual case of ACS. As one of the important components, the ACS TE-Cloud (Test Engineering Cloud) was originated in China, developed by Advantest to meet the needs of the Chinese market. China's IC design companies are developing rapidly, but they are generally small and dense. They don't necessarily have access to the latest and greatest hardware. However, they need access to that technology in order to develop their test programs. ACS TE-Cloud provides these companies with a virtual environment in the cloud, where they can log in, access, write and execute test programs. No need to worry about resource acquisition, system maintenance, etc., which effectively reduces their costs for test development.

Michael: Compared with the leading fabless companies worldwide, there are a lot of relatively young semiconductor design companies (fabless) in China. That means they don't have a lot of experience with semiconductor testing and assembly. For example, the Exensio platform, a key part of this joint product offering with Advantest, incorporates a great deal of embedded best-practice knowledge. It also comes with a robust set of analysis and template libraries. Users can develop new products based on these best-practice experiences. This can greatly improve the efficiency of their product development iterations.

Sonny: The Chinese market not only has a large demand for analytics, but also leads the world in analytics applications and technologies. One forecast shows that China is projected to be the third largest global spender on big data analytics. Therefore, in my opinion, the next important action is to provide the right products and solutions, so that the products we jointly develop can create more value for customers in the Chinese market. Just as the ACS TE-Cloud was originated and promoted in China, we will continue to cooperate to develop more products and applications based on the needs of the Chinese market.

David: In my opinion, China may be able to move faster in leveraging semiconductor data analytics that the overall semiconductor industry. A lot of IC design companies in China are relatively young, which means that they are also more likely to take advantage of the latest data analysis systems, and do not have to face the problems of how to deal with older or legacy systems, which many large, traditional semiconductor companies may experience.

JIWEI: In terms of empowering the semiconductor industry with intelligent means such as big data analysis, cloud, and AI, what are the new trends in the future?

Keith: I would like to draw an analogy with testing and evaluating football (soccer) players. Not all players are going to play all positions. For example, the goalkeeper, may need to be tall with a really long arm span, whereas requirements for strikers are completely different. So how to test and evaluate people for those positions? Obviously, we need customized test scenarios for different locations. But for a long time, the industry usually used a one-size-fits-all general test solution. However, with the increasing complexity of semiconductor process technology and the diversity of application requirements, the quality requirements for electronic components such as chips will also be different. Moreover, in the current environment of supply chain shortages, optimizing the test plan with different quality requirements for devices and use the big data analytics to control the test cost is vital. This is also what we are doing in cooperation with PDF Solutions.

Sonny: In the future, we will also tap the potential of more artificial intelligence based on machine learning to develop more killer applications . Advantest and PDF have worked together for a year and we understand each other. And we look forward to working together to elevate the power of machine learning to a new level in semiconductor testing and data analysis, to do some predictive analytics, etc.

Michael: I would also like to add one last thing. As technology progresses, the manufacturing process becomes more and more complex; in addition, as the chip size increases, there are more and more functions, which means that the amount of testing will also increase, and the whole process will generate an increased amount of data. And how to effectively leverage all of this data through machine learning, artificial intelligence, cloud computing and other methods, including data mining, to improve the overall efficiency of semiconductor manufacturing and optimize costs, will become more and more important.

READ MOST

No Data Yet~