By Kate Yuan

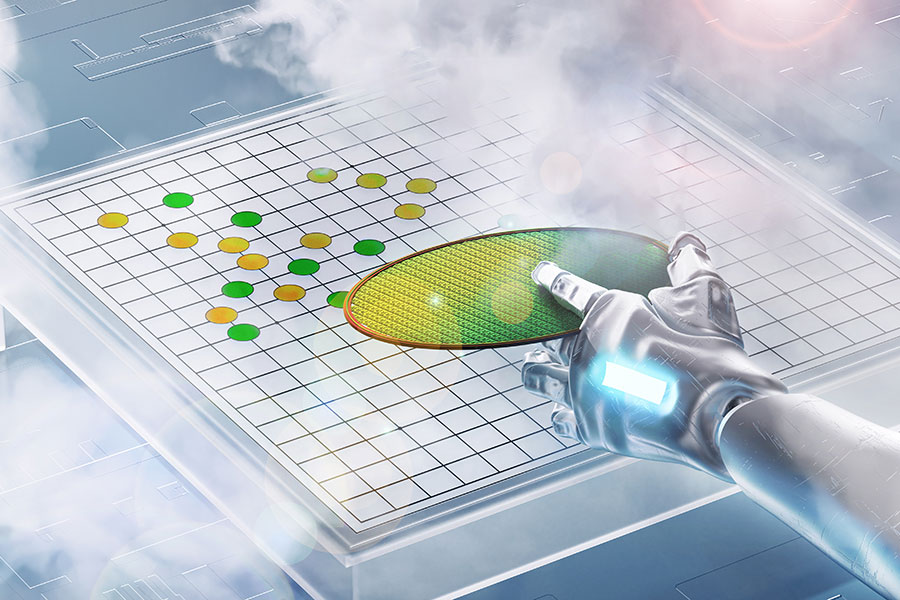

(JW Insights) Aug 2 -- China's domestic equipment manufacturers have been making significant progress in the field of crystal growth and wafer cutting, gradually forming a new force and challenging the dominance of foreign equipment manufacturers, DIGITIMES Asia reported on July 31.

Notable Chinese companies in this domain include the likes of Han's Laser Technology Industry Group (大族激光), Suzhou Maxwell Technologies (迈为科技), and China Great Wall (中国长城).

Recently, HGTECH (华工科技) also announced the successful technical breakthroughs and the launch of China's first domestically produced wafer laser cutting equipment with 100% locally sourced components. After years of upgrades, its wafer cutting technology has reached a mature stage.

The company is currently developing the wafer laser cutting equipment for SiC and GaN semiconductors, which is expected to be launched soon. They are also working on developing a proprietary intellectual property for SiC/GaN wafer laser annealing equipment.

Until now, the global wafer laser cutting market has been primarily dominated by companies such as Disco, KLA, K&S, UKAM, and Ceiba. However, Chinese companies have been actively pursuing domestic alternatives to meet the growing industrial production demand. They have been adopting domestically manufactured and assembled laser cutting equipment.

In the past, equipment for the front-end crystal rod cutting process mainly came from Japanese and Korean suppliers, but in recent years, especially in the Yangtze River Delta region, several domestic suppliers have emerged. Zhang Rujing, SMIC founder and now the executive director of GTA Semiconductor, observed that the current local equipment for cutting crystal rods into silicon wafers has caught up with the Japanese manufacturers in terms of technology yield and quality.

The localization of equipment in Chinese wafer fabs involves collaborative efforts from both upstream and downstream manufacturers. XinSheng Semiconductor Technology, China's largest silicon wafer manufacturer, is actively cooperating with Chinese domestic equipment manufacturers to promote the comprehensive localization of the semiconductor wafer cutting process.

Qiu Ciyun, a former SMIC executive and now Xinsheng's CEO, stated that they are actively working with local manufacturers to enhance the role of Chinese domestic equipment in the supply chain. Over the past five years, Xinsheng has been working on localizing equipment, including the core crystal pulling equipment, and has already achieved certification for local production through collaboration with equipment manufacturers, said the DIGITIMES Asia report.

RELATED

-

Chinese top-tier chipmaker HuaHong Semiconductor's net profit plummets 86 percent in the third quarter

11-17 19:11 -

NBS: China’s specialized equipment manufacturing industry for semiconductor devices sees 33.9% surge in value added in October

11-17 17:41 -

Chinese MEMS provider Fatri UTC will set up its sensor chip production plant in Shanghai

11-16 18:30

READ MOST

No Data Yet~